The Best Strategy To Use For Watry Industries

Watry Industries Things To Know Before You Get This

Table of ContentsOur Watry Industries StatementsThe Main Principles Of Watry Industries A Biased View of Watry Industries5 Easy Facts About Watry Industries DescribedThe 4-Minute Rule for Watry IndustriesA Biased View of Watry IndustriesWatry Industries Things To Know Before You BuyThe 10-Second Trick For Watry Industries

(https://moz.com/community/q/user/w4t8yalumnim)The Torchmate 4505 is an effective plasma cutter with a 5x5 cutting table. A circulation Industries 4'x4' waterjet cutter solution is available for sure projects. Access varies relying on the part geometry along with the number of components that require to be cut - aluminum metal casting. A budget number will require to be provided for operator/programmer time.

The C15 car park lives between both structures. You will certainly need to register for shop security courses prior to you can access the store. The shop is for servicing official UW funded tasks including trainee technical clubs and official research study. All store customers have to be an energetic pupils, team, or professor of the University of Washington.

An Unbiased View of Watry Industries

Guests must register personally, and we advise entering early, since the courses fill very quickly, within a half-hour of being published. If you aren't below early, it's unlikely you will enter. The safety and security classes are totally free and except credit. They are held on three separate days, each a week apart, and each course is about 2 hours long.

If you can not attend the safety classes held during a particular quarter, the soonest you will be able to complete them is at the start of the following quarter. Other shops that allow student access besides ours here on campus: We don't do much work for hire any longer, due to the substantial tons of students we have to monitor, as well as various other upkeep and shop enhancement.

Some Known Factual Statements About Watry Industries

When it comes to gas and vapor power generation, all manufacturing processes need to be function precisely and comprise of parts and elements that can work effectively under significant stress. Valves, such as ball shutoffs, gate valves, and piston valves, are all steel parts that call for the usage of CNC equipment. Codes can be configured right into the CNC equipment and be used to make great cuts according to a particular size and weight to support industrial applications.

What Does Watry Industries Do?

The Store and its team concentrate on study and academic environments, testing fixtures and fabrications of all sizes. Our services are readily available to all departments in the College of Engineering as well as various other colleges and scholastic departments at the University of South Florida. Layout help, repairs, construction and assembly using a large range of materials, including steel, stainless steel, light weight aluminum, plastics and wood Complete complement of contemporary precision tooling and machinery, consisting of CNC (Computer Numerical Controlled) machining using FeatureCAM CNC software application that can transform SolidWorks and AutoCAD data to satisfy your layout click now needs Our store is completely outfitted with various welders consisting of TIG, MIG, Stick welders and a Plasma Cutter Our timber store uses a variety of woodworking machinery, equipment and hand tools for milling, exploration and reducing wood and plastic CNC Milling Machines CNC Lathe Guidebook Milling Machines Manual Milling Lathes Surface Mill Radial Arm Drill Press Vertical Bandsaw Horizontal Bandsaw Cold Saw Rough Cut-Off Saw Oxy-Acetylene Lantern Plasma Cutter TIG Wedler MIG Welder Stick Welder Hand-held Spot Welder Shear Bending Brake Beverly Shear Tubes Bender Notcher Drill Press Arbor Press 17.5 Ton Hydraulic Press Barrier Drill Grinder Different Guidebook and Power Hand Tools.

Sadler Maker Co - machine shop. is a highly acknowledged CNC maker store, task store, upkeep, and proto-type machining business located in the heartland of America, in Cedar Rapids, Iowa

Machining is an umbrella term that is made use of to develop parts by eliminating product from a strong work surface. In the past, machining was normally made use of for steels, however today it is also made use of for plastics and a range of other unique materials. Machining can consist of boring, boring, turning, reducing, milling, knurling and even grinding to produce the certain required shape.

The 25-Second Trick For Watry Industries

CNC machining is additionally referred to as Computer Numerical Control machining, and it utilizes the precision of a computer to manage the details device and device in the machining process. In this kind of machining, accuracy is the focus, with the device and the machine making the precise same elimination of the material from the work surface with every unit.

Watry Industries Fundamentals Explained

Machining. Machining facilities are multifunctional items of devices capable of carrying out complex procedures at high production prices. Lathe.

Grinding device. A grinding device is a kind of power tool that makes use of a rough wheel to grind the workpiece. Grinding is generally used as a finishing process, because it provides a high surface quality. Pierce press. A drill press is a sort of installed drill whose activity is controlled by a lever.

Bandsaw. A bandsaw is a multi-use cutting maker made use of to make straight cuts. It is utilized for about getting rid of areas of material before further cutting. EDM tools. Electrical Discaharge Machining (EDM) is a procedure that makes use of stimulates rather of a physical reducing device to pass through the work surface. Alternative variations of the technology utilize a wire for the tool electrode.

Facts About Watry Industries Uncovered

Machines accomplish various production operations, and may be either manual (run by a machinist) or outfitted with Computer Numerical Control (CNC) modern technology. Besides equipment, an equipment store might also contain shops of resources that can be machined to make components. Depending on the range of the producer, products may be saved elsewhere, in a storehouse.

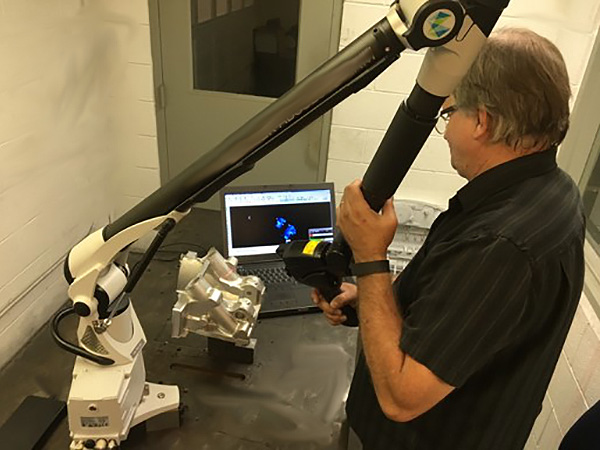

Digital 3D designs are converted right into G-Code, which informs the CNC equipment what to do in order to create the 3D form. Every activity of the reducing tool - Foundry is managed to millimeter accuracy by the program, which enables the equipment to generate perfect duplicate parts to a tright resistance without mistake

Some machines, such as 5-axis CNC mills, have swiveling spindles or tables, which enables the cutting device to reduce the block of product from any kind of angle without disturbance. The 5-axis CNC machining technology can device parts very rapidly, which is beneficial for equipment stores generating large quantities of parts for significant projects.

Get This Report about Watry Industries

Additionally, machinists functioning at CNC machine stores are generally experienced in digital layout and consequently qualified of tailoring digital designs for CNC machining. Nearly all CNC machinists have experience in hands-on machining, as this skill aids them better understand the CNC machining procedure. Moreover, a CNC factory will typically be qualified of functioning from electronic CAD data, technological illustrations or a combination of both.